What Are Load Testing Machines And Why Are They Important?

The Anatomy of a Load Testing Machine

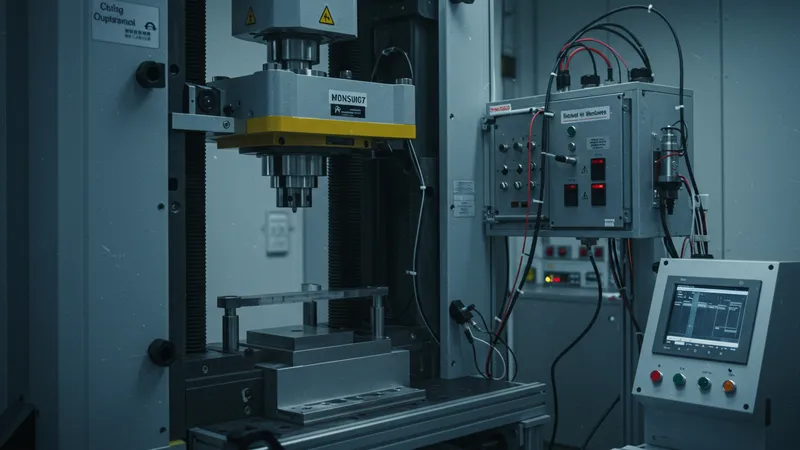

At first glance, a load testing machine might seem like just a heap of metal and wires. On closer inspection, it becomes apparent they are intricately designed to mimic real-world stresses on materials. A typical machine consists of hydraulic presses, sensors, and sophisticated feedback systems, allowing precise measurements and adjustments in real-time.

These machines handle diverse tests like tension, compression, and fatigue – each essential for evaluating different material properties. For instance, tension tests measure the force required to pull something apart, revealing its robustness. But how these machines adapt to various materials is where their true genius lies…

Customization is key. Each material and structure presents unique challenges, prompting developers to innovate devices tailored specifically for those needs. Unexpectedly, this adaptability underscores an unheard-of economic and safety advantage within industries, reducing waste and ensuring structures that are beautifully efficient yet inherently safe.

It’s not just about steel and concrete; load testing machines are pivotal for advanced materials like composites used in future-mobilizing technologies. As these innovations march forward, so too does the demand for testing capabilities that keeps pace. The revelations that follow could redefine industry standards forever…