Mining Equipment Suppliers: Everything You Need To Know Before Making A Purchase

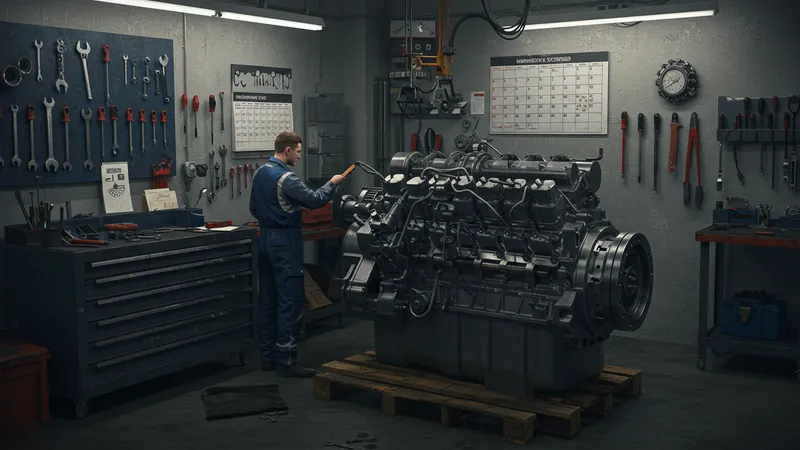

The Power of Simple Maintenance Hacks

Simple maintenance hacks can exponentially increase your equipment lifespan without blowing your budget. Regular inspections and preventative measures prevent costly breakdowns and ensure compliance. Embracing straightforward practices quietly revolutionizes operations by extending equipment productivity and enhancing reliability.

Misalignment between maintenance schedules and actual wear patterns results in accelerated depreciation and unexpected downtimes. Adopting precise maintenance timelines tailored to specific equipment allows for offsetting deterioration and optimizing lifespan. Discovering the efficacy of routine checks may awaken new maintenance strategies steeped in proactive care.

Technological integrations with maintenance protocols streamline operations and create efficiencies previously unattainable. Sensors and remote monitoring provide real-time analysis, minimizing human error and maximizing insights. By leveraging tech-driven approaches, the mysteries of equipment wear can be revealed and addressed promptly.

Training personnel to execute fundamental maintenance techniques fosters ownership and accountability within teams. By imbuing staff with skills that prioritize tangible results and allow for fluid troubleshooting, organizations can manage more effectively. The next stage in maintenance innovations holds revelations that could reshape protocol standards on a grand scale.