How Laser Cutting Is Revolutionizing Modern Manufacturing

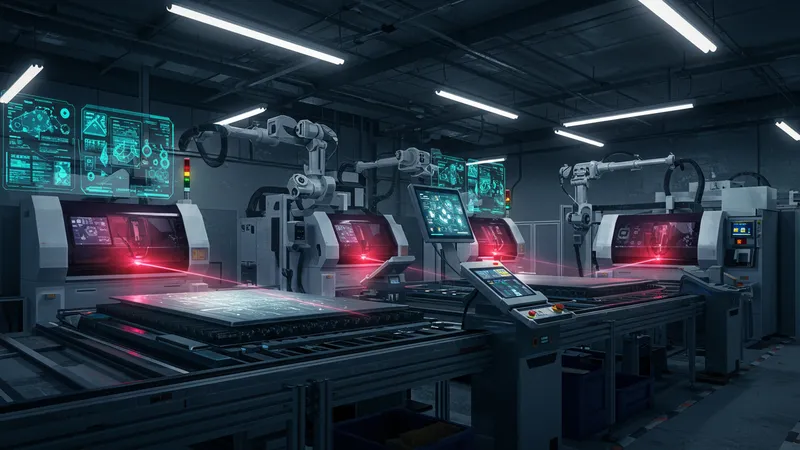

The Future of Smart Manufacturing

Laser technology is at the heart of smart manufacturing. With advancements in AI and machine learning, laser systems are becoming increasingly autonomous. This self-optimization means high precision with minimal human intervention.

The integration of smart technology allows machines to communicate, monitor, and troubleshoot in real-time. The effect is a streamlined production line that maximizes efficiency while minimizing downtime. But that’s just scratching the surface…

Predictive maintenance, facilitated by smart laser systems, anticipates equipment failure before it happens, reducing unexpected costs. This innovation not only saves money but also ensures uninterrupted production cycles.

As industries continue to embrace smart manufacturing, the synchrony between design and production becomes seamless. This convergence could lead to groundbreaking products that change our daily lives, bridging the gap between imagination and reality.