How Laser Cutting Is Revolutionizing Modern Manufacturing

The Hidden Advantages of Laser Precision

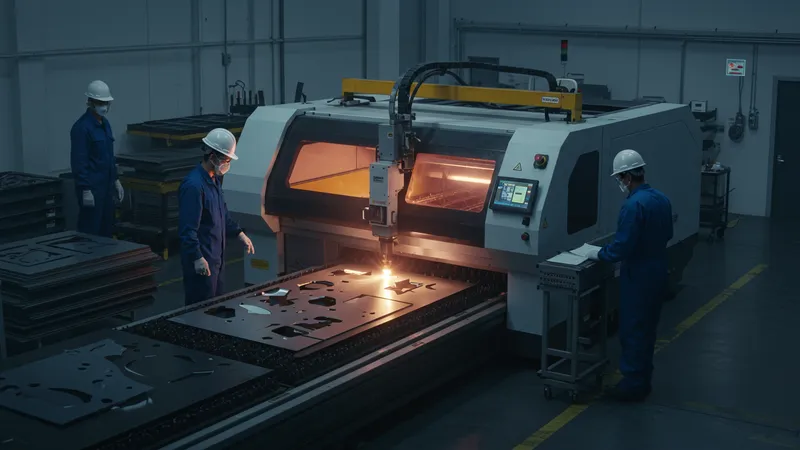

Laser cutting’s precision is unmatched, achieving tolerance levels that traditional methods can’t. This exactness is crucial for sectors like aerospace, where the margin for error is non-existent. But there’s one more twist… it drastically reduces the time needed for prototyping, transforming innovation cycles.

Industries are adopting laser technology not just for precision but for its versatility. Materials like metal alloys, plastics, and even glass can be efficiently cut. As a result, manufacturers cater to diverse market needs with ease. What you read next might change how you see manufacturing forever.

Many assume laser cutting is limited by material thickness. However, advanced machines can handle even thicker materials, contradicting common beliefs. This opens up avenues for large-scale architectural projects, previously thought impossible. But that’s not all.

Insiders know that laser cutting isn’t just about cutting. Engraving and marking features open new branding possibilities for companies seeking unique product differentiation. The next revelation could redefine how brands engage consumers.